AlSiC

Smart parts powering the big picture.

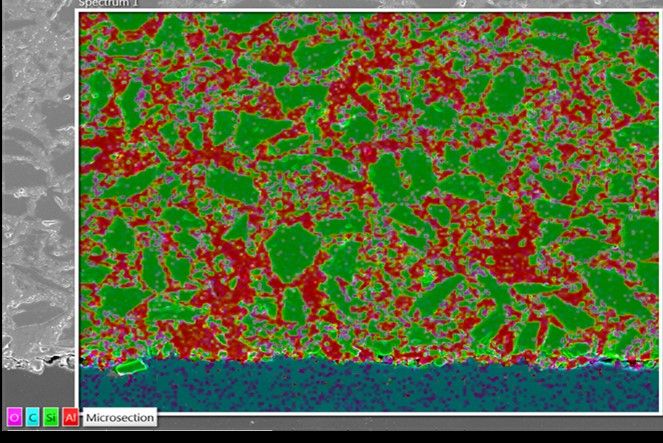

A&1 has spent more than 40 years creating world-class solutions for plating and metal matrix composites. We bring the AlSiC for our clients to carry out the reliable product of IGBT module , CPU, GPU. We also create the new technology of flip CSP to help customer implement 100% Pb free Schottky devices to meet ESG requirement

Cap for GPU, HPC CPU

Due to the rising applications of 5G and AI, the capability and power consumption of processors have also risen sharply. As the speed of processors increases and the heat energy generated by the increase in power also increases, the conventional copper cap or stainless steel cap is prone to warping by thermal expansion and contraction. The low expansion coefficient of AlSiC is especially suitable for high-power CPU, GPU, making the produce itself superior reliability in applications.

GPU, HPC CPU heatsink

Due to the rising applications of 5G and AI, the capability and power consumption of processors have also risen sharply. As the speed of processors increases and the heat energy generated by the increase in power also increases, the conventional stainless surrounding heatsink is prone to warping by thermal expansion and contraction. The low expansion coefficient of AlSiC is especially suitable for high-power CPU, GPU, making the produce itself superior reliability in applications.

IGBT heatsink

IGBT power modules are best choice for high-power applications such as electric vehicles. IGBT power modules are mainly used as electrical switches in vehicles. The transfer switch can convert direct current (DC) into alternating current (AC) as a power source for motor drive, and vice versa for charging. Its high power generates a great deal of heat. The current heat dissipation technology adopts the water cooling system, but the traditional copper heatsink will warp due to the large temperature difference between the IGBT that generates the heat source and the water flow of the heat dissipation circulation below, resulting in the sealing and rupture of the heat dissipation circulation water tank making water leakage, resulting in quality accident and even worse leads life’s dangers. The high rigidity and low expansion coefficient of AlSiC can perfectly solve this adhesion problem. It makes the IGBT module and water cooling system performing the best quality.

Antenna for Industrial and military

In radio, radar, and space-based RF systems operating at hundreds of MHz and tens of GHz, the signal is coefficient with temperature of antenna . The concept of antenna noise temperature is critical in understanding how the antenna contributes to the system noise in low-noise receiving systems such as radio astronomy and radiometry. It is also important in understanding the relation between an object’s temperature and the power generates at the

receiving antenna terminals. General industrial or military antennas especially need to adapt to various harsh outdoor conditions. The high rigidity and low expansion coefficient of AlSiC fully meet this special application situation.

Semiconductor Wafer tooling

Semiconductor wafers need to be cleaned, baked and other processes during the production process. As the wafer size increases, or the substrate material changes (such as silicon carbide), the stress or temperature of the fixture will change greatly. Traditional stainless steel fixtures are unable to cope with such temperature and stress changes, causing quality concerns in the wafer production process.

The high rigidity and low expansion coefficient of AlSiC perfectly solve the problem of the deformation of the fixture, and solve the problems of the production line of the wafer factory due to the deformation of the production mold or the failure of the test.

![]()

Semiconductor testing tooling

Semiconductor devices must be 100% tested before shipment. During the test, there are contact stress and heat generated by the test current, which make the tooling warpaged. The traditional stainless steel support fixture will warp due to continuing on-line contact stress and also bigger size of tested processor .The high rigidity and low expansion coefficient of AlSiC perfectly solve the problem of the deformation of the jig, and solve the problems of the production line of the packaging and testing factory due to the deformation of the test mold or the failure of the test.

![]()